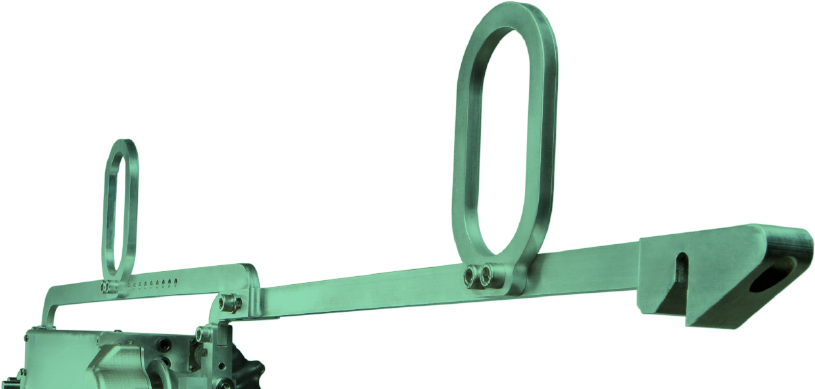

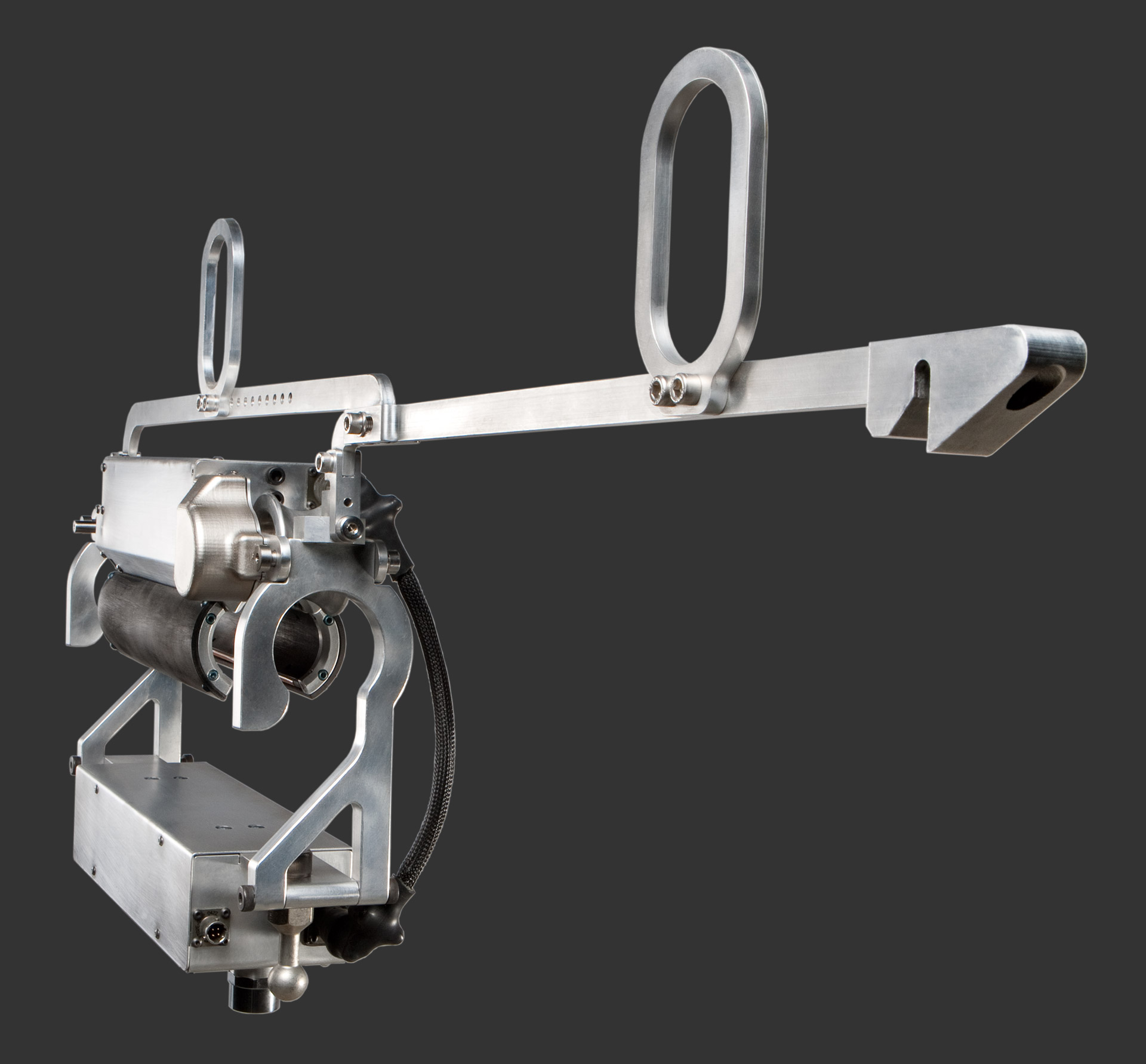

LineCore – A corrosion detector for ACSR conductors

LineCore determines the condition of the galvanic protection on transmission and distribution line conductors, even when they are energized. It accurately measures the thickness of the layer of zinc across an entire span, detecting anomalies caused by corrosion with a minimum of sampling.

It is the perfect tool for obtaining detailed information on the condition of aluminum conductor steel reinforced (ACSR) conductors.

The data collected by LineCore can be used to calculate conductor degradation and help evaluate its remaining service life.

LineCore benefits

- Continuity of service: Non-destructive inspections without sampling or service interruptions

- Ease of use: Simple-to-use software for calibration, inspection, archiving and analysis

- Ease of interpretation: Results categorized into five grades of wear

- Versatility: Compatible with all types and gauges of ACSR conductors

- Flexibility:

- Embedded on LineROVer – Runs along single conductors and ground wires, able to negotiate splice sleeves

- Embedded on LineScout – Runs along conductor bundles, single conductors and ground wires and able to negotiate most obstacles

- Ruggedness: Designed for use on worksites and in hostile environments

LineCore applications

- Inspection of the zinc layer on entire spans, and on consecutive spans when mounted on LineScout

- Inspection of ACSR conductors and overhead steel ground wires

- Deployment on single- and bundled-conductor circuits

Typical LineCore use cases

- Hard-to-reach segments, such as spans in mountainous or agricultural regions and water, distribution line, highway and railway crossings

- Lines exposed to conditions likely to reduce equipment service

life:

- Marine climate, atmospheric pollution

- Areas subject to adverse weather conditions (wind, lightning, ice, etc.)

- Strategic segments where continuity of service is essential (interconnection with neighboring systems, supplies to industrial or densely populated areas)

Value creation

- Increased productivity compared to other inspection and repair methods

- Reduced asset downtime

- Non-destructive in situ evaluation methods

- Precise and detailed data to support maintenance decisions

- Reduced costs through deferred capital spending

- Prioritization of asset maintenance projects

- Extended equipment service life

- Risk reduction, increased asset stability and reliability

- Enhanced worker health and safety

Specifications

- Weight: 4.5 kg

- Dimensions: 40 cm L x 35 cm H x 10 cm W

- Conductor diameter: 15 to 40 mm

- Inspection speed: up to 1.0 m/s

- Compatible stranding: 12x7, 30x7, 54x7 and others

- Grading of zinc thickness: Sound, 13 to 20 µm, 5 to 13 µm, < 5 µm and Aluminum erosion (5 grades)

- Distance logger: Integrated

- Battery life: 8 hours

- Operating temperature: −10°C to +35°C