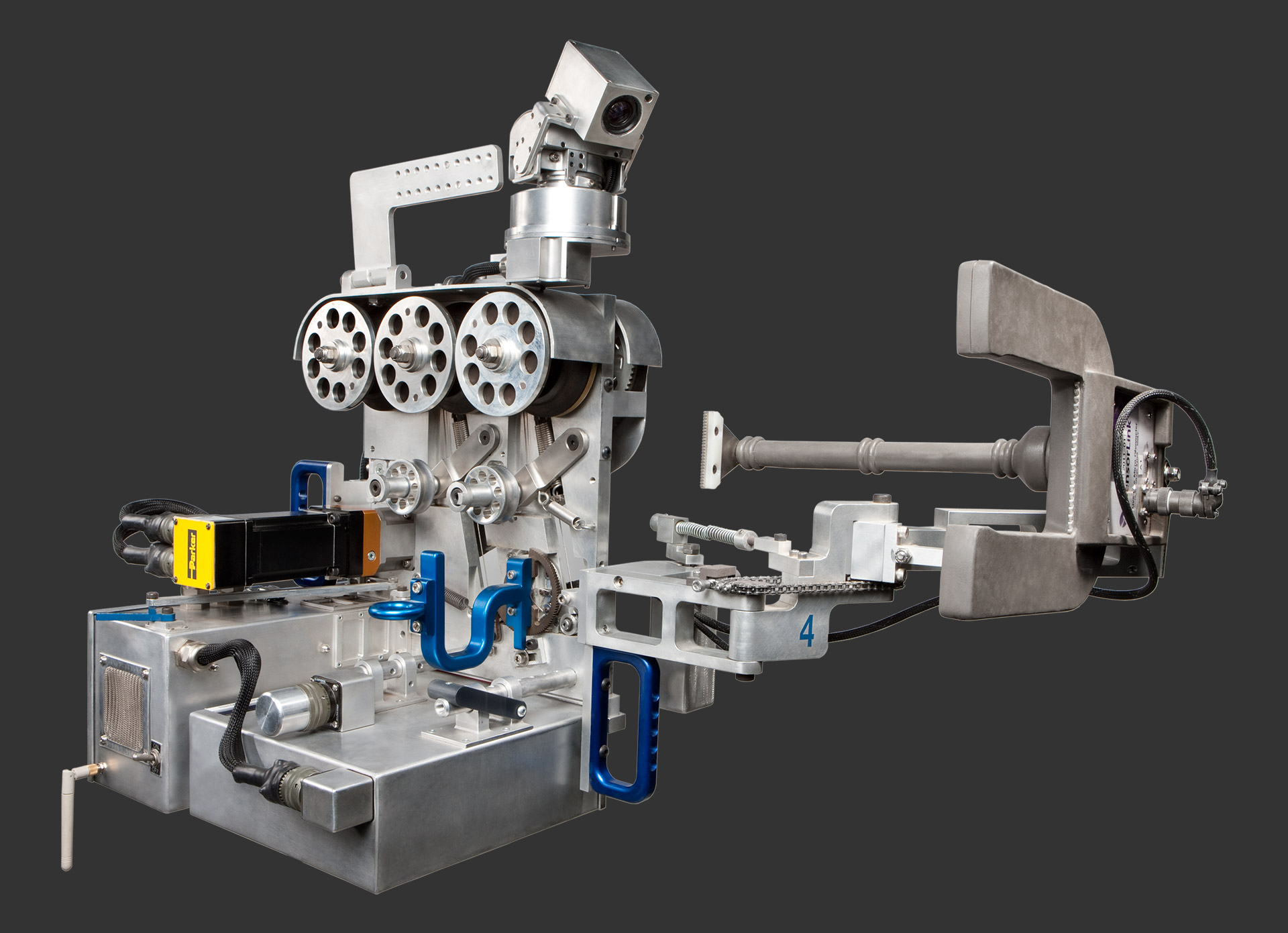

LineROVer – A compact robot for inspecting overhead lines

The lightweight and compact LineROVer was originally developed for de-icing overhead ground wires and conductors. Over time, many additional overhead transmission line inspection and maintenance applications have been found for this remotely-operated robot that can operate even on energized lines.

LineROVer is simple to use and install and is the ideal tool for a wide range of work in hard-to-reach locations.

LineROVer benefits

- Continuity of service: Works on energized lines without interrupting service

- Lightweight: 23-kg vehicle that can be used on small-gauge cables

- Portability: Compact for easy transportation and deployment

- Simplicity: Easy to operate

- Flexibility: Able to negotiate splice sleeves

- Versatility: Compatible with most conductor types

- Ruggedness: Reliable mechanical and electronics systems

- Very high traction

LineROVer applications

- Visual inspection

- Verification of splice condition (by measuring resistance)

- Infrared imaging

- Corrosion detection (using the LineCore sensor)

- Overhead ground wire and conductor de-icing

- Replacement of conductors, overhead ground wires and optical ground wires (OPGW) using the cradle block method

- Conductor repair

Typical LineROVer use cases

- Hard-to-reach segments, such as spans in mountainous or agricultural regions and water, distribution line, highway and railway crossings

- Lines exposed to conditions likely to reduce equipment service

life:

- Marine climate, atmospheric pollution

- Areas subject to adverse weather conditions (wind, lightning, ice, etc.)

- Strategic segments where continuity of service is essential (interconnection with neighboring systems, supplies to industrial or densely populated areas)

Value creation

- Increased productivity compared to other inspection and repair methods

- Reduced asset downtime

- Non-destructive in situ evaluations

- Precise and detailed data to support maintenance decisions

- Reduced costs through deferred capital spending

- Prioritization of asset maintenance projects

- Extended equipment service life

- Reduced risk and increased asset stability and reliability

- Enhanced worker health and safety

Specifications

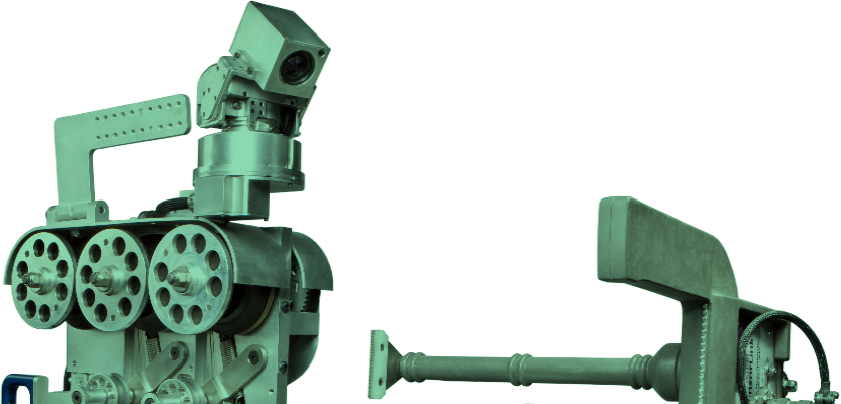

Click to enlarge

- Weight: 23 kg

- Dimensions: 44 cm L x 64 cm H x 40 cm D

- Conductor diameter: 10 to 37 mm

- Maximum splice sleeve diameter: 55 mm

- Continuous traction: 670 N

- Battery life: 45 minutes to many hours, depending on task

- Remote control range: 1 km

- Electromagnetic immunity: 315 kV/1000A

- Operating temperature: −10°C to +35°C