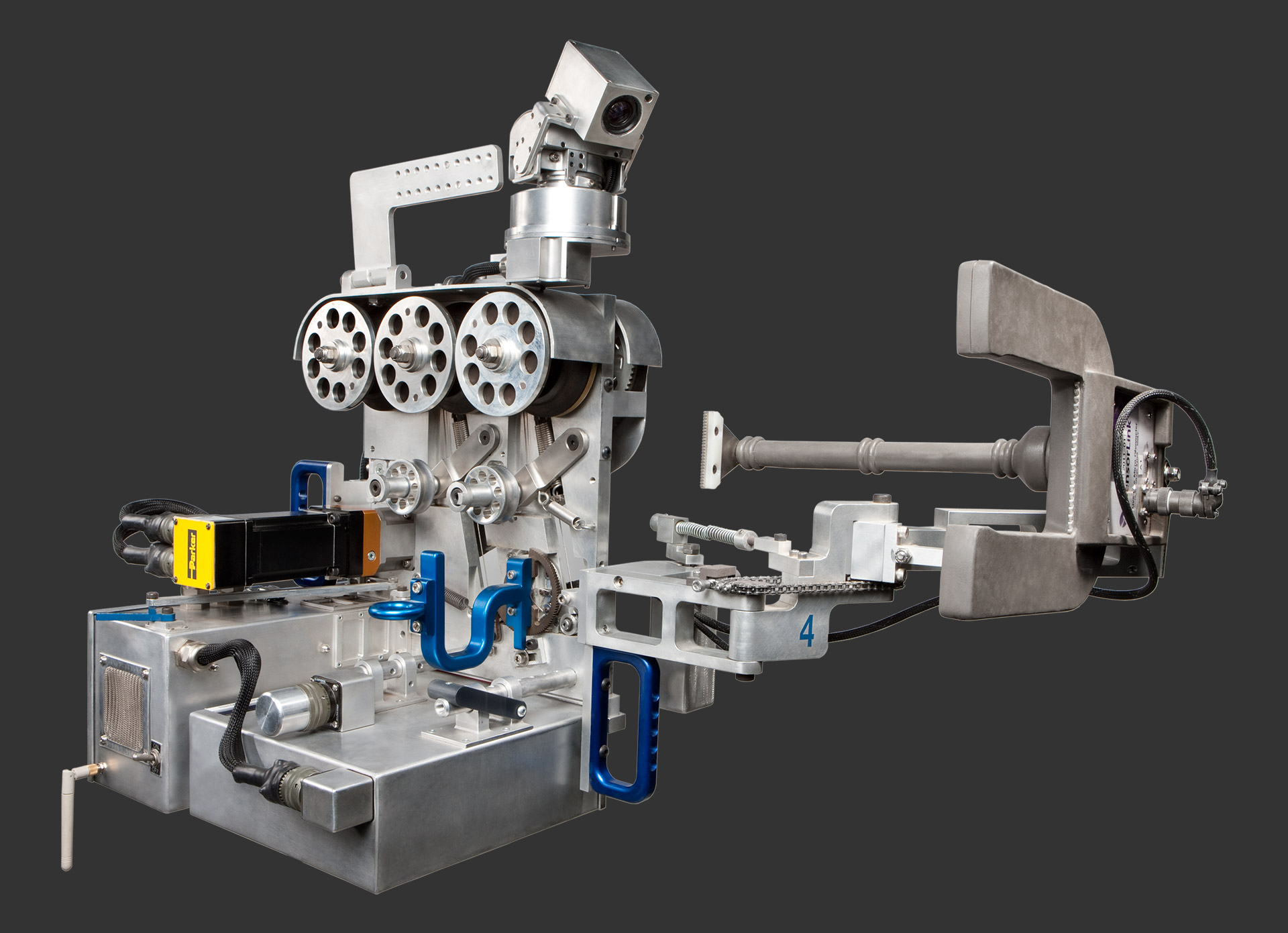

LineROVer – A compact robot for inspecting overhead lines

The lightweight and compact LineROVer was originally developed for deicing overhead ground wires and conductors. Over time, many additional overhead transmission line inspection and maintenance applications have been found for this remotely-operated robot that can operate even on energized lines.

LineROVer is simple to use and install and is the ideal tool for a wide range of work in hard-to-reach locations.

LineROVer benefits

- Continuity of service: Works on energized lines without interrupting service

- Lightweight: 23-kg vehicle that can be used on small-gauge cables

- Portability: Compact for easy transportation and deployment

- Simplicity: Easy to operate

- Flexibility: Able to negotiate splice sleeves

- Versatility: Compatible with most conductor types

- Ruggedness: Reliable mechanical and electronics systems

- Very high traction

LineROVer applications

- Visual inspection

- Verification of splice condition (by measuring resistance)

- Infrared imaging

- Corrosion detection (using the LineCore sensor)

- Overhead ground wire and conductor de-icing

- Replacement of conductors, overhead ground wires and optical ground wires (OPGW) using the cradle block method

- Conductor repair

Typical LineROVer use cases

- Hard-to-reach segments, such as spans in mountainous or agricultural regions and water, distribution line, highway and railway crossings

- Lines exposed to conditions likely to reduce equipment service

life:

- Marine climate, atmospheric pollution

- Areas subject to adverse weather conditions (wind, lightning, ice, etc.)

- Strategic segments where continuity of service is essential (interconnection with neighboring systems, supplies to industrial or densely populated areas)

Value creation

- Increased productivity compared to other inspection and repair methods

- Reduced asset downtime

- Non-destructive in situ evaluations

- Precise and detailed data to support maintenance decisions

- Reduced costs through deferred capital spending

- Prioritization of asset maintenance projects

- Extended equipment service life

- Reduced risk and increased asset stability and reliability

- Enhanced worker health and safety

Specifications

- Weight: 23 kg

- Dimensions: 44 cm L x 64 cm H x 40 cm D

- Conductor diameter: 10 to 37 mm

- Maximum splice sleeve diameter: 55 mm

- Continuous traction: 670 N

- Battery life: 45 minutes to many hours, depending on task

- Remote control range: 1 km

- Electromagnetic immunity: 315 kV/1000A

- Operating temperature: −10°C to +35°C