Building the needed power lines or transmission substations

Power lines are like the roads the electricity takes to get from A to B, while substations are like a crossroads policeman directing the electricity to Québec’s cities and towns. Just like a road network, power lines have different carrying capacities.

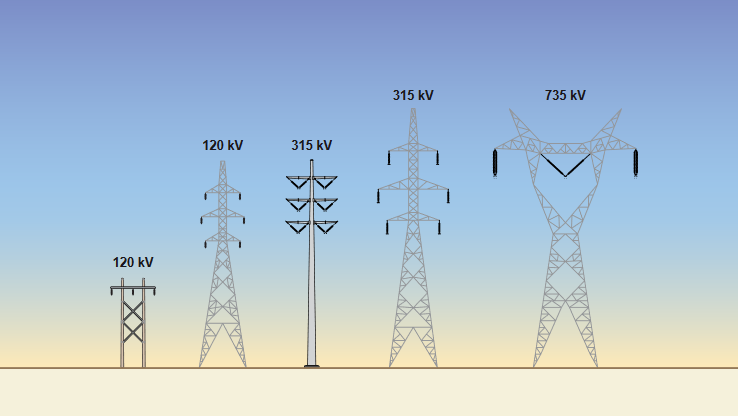

Based on the needs identified, a power line construction project may aim to build a “highway” (735‑kV line), a “main road” (315‑-kV line) or a “secondary road” (120‑kV line). Such projects may also include building one or more substations.

Whenever a line or substation must be added to the grid, the design, permitting, and construction processes are conferred to a project team.

From drawing board through commissioning, this team sets out to deliver the best possible project in consideration of both energy needs and a range of social, environmental, technical and economic concerns.

Our goal:

to continue to provide Quebecers with clean, reliable and affordable power.

Our mindset:

work together toward development that is sustainable so that the projects we undertake today may benefit tomorrow’s Québec.

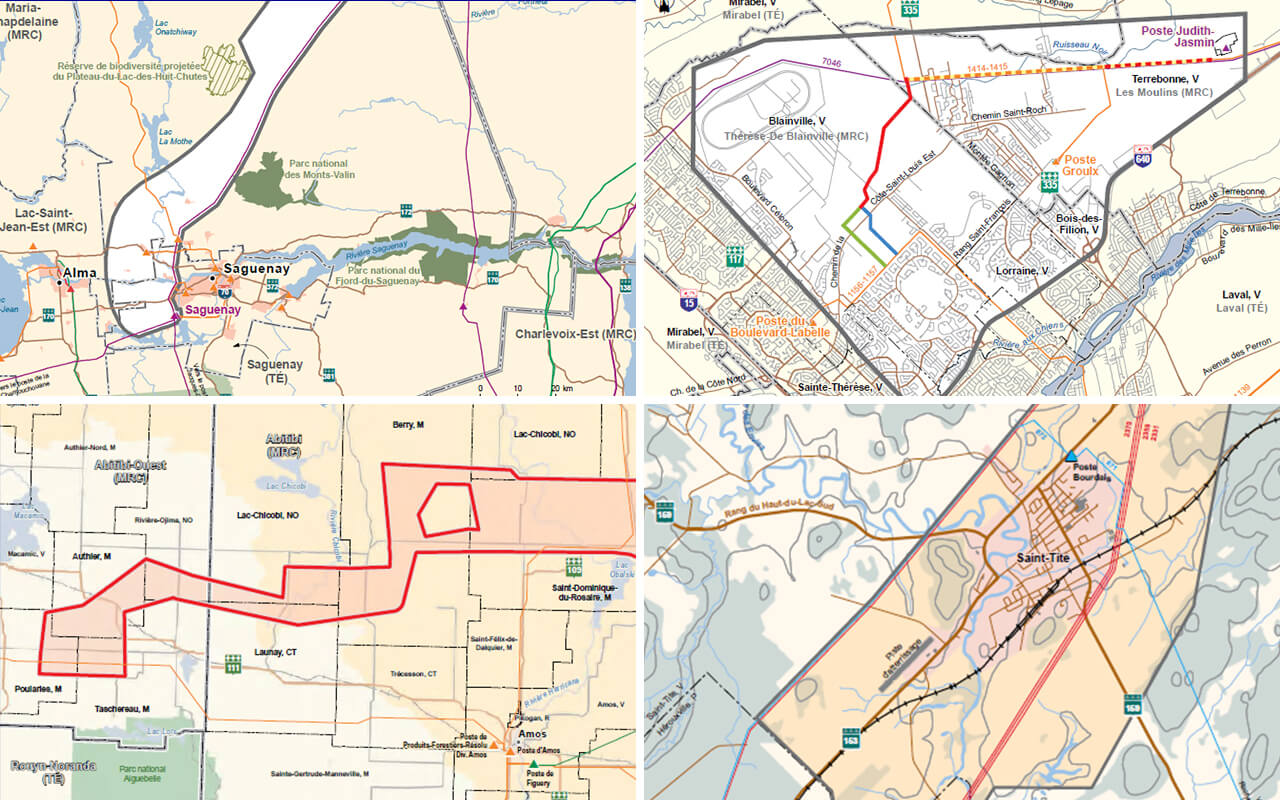

Study area for a power line or transmission substation construction project

Of course, delivering the best possible project calls for detailed, in-depth knowledge of the site and its surroundings. The project team lays out an area between the place(s) to be supplied with power and the transmission system connection point. This area is the project study area.

Technical and environmental studies and public consultations

Once the study area has been defined, the project team initiates a dialogue with the communities concerned and conducts technical and environmental studies. Together, these processes aim to identify the best line route and substation location.

The range of studies to carry out can be astonishing. These studies can vary based on the type of project and the setting in which it is to be built.

Examples of technical and environmental studies

- Inventory of existing infrastructures and technical constraints: roads, gas pipelines, railways, airports, telecommunications antennas, waterworks, etc.

- Geotechnical surveys: determining local topography and soil analysis

- Inventory of land use: residential areas, farming, tourism and recreational activities, commercial and industrial activities, protected areas, etc.

- Inventory of plants and wildlife, identifying special-status species

- Consulting the land use plans of the RCMs concerned

- Archaeological surveys, studies on the landscape, soil, wetlands, noise levels, etc.

Examples of project stakeholders and organizations we meet

- Elected officials and local administrators

- Indigenous communities

- Land users: hunters, fishers, hikers, cyclists, etc.

- Representatives from economic development, recreational tourism, environmental, agricultural and forestry organizations/associations

Throughout the project, the team will use various means to contact project stakeholders and launch a constructive dialogue. These means include public meetings, announcements in local and social media, a project website, airwave time on the radio, electronic or print newsletters, a dedicated phone line and/or online consultations.

Opportunities to dialogue with the community

Discussions with the communities most affected by a line or substation construction project generally unfold in three stages.

Project presentation

The project team meets with members of the community concerned to present the rationale for a new facility, the study area and to discuss the upcoming public consultation process.

Public consultations

After conducting part of the technical and environmental studies and collecting the first findings from the host environment, the team draws a line route (and possibly some route variants) and/or identifies one or more possible substation locations.

The team then determines:

- How the public consultation process will unfold

- The substation location(s) and the line route(s)

- The pros and cons of each line variant or substation location

Our discussions with community organizations, potentially affected landowners, land users, and citizens help further our analysis and respond to concerns expressed

This stage is normally where the most meetings take place. The emphasis here is on achieving the greatest possible consensus.

We aim to have our power transmission facilities (lines and substations) blend harmoniously into their surrounding environment. The best way to achieve this and mitigate the impact is to work together to make the best possible choice of line route or substation location.

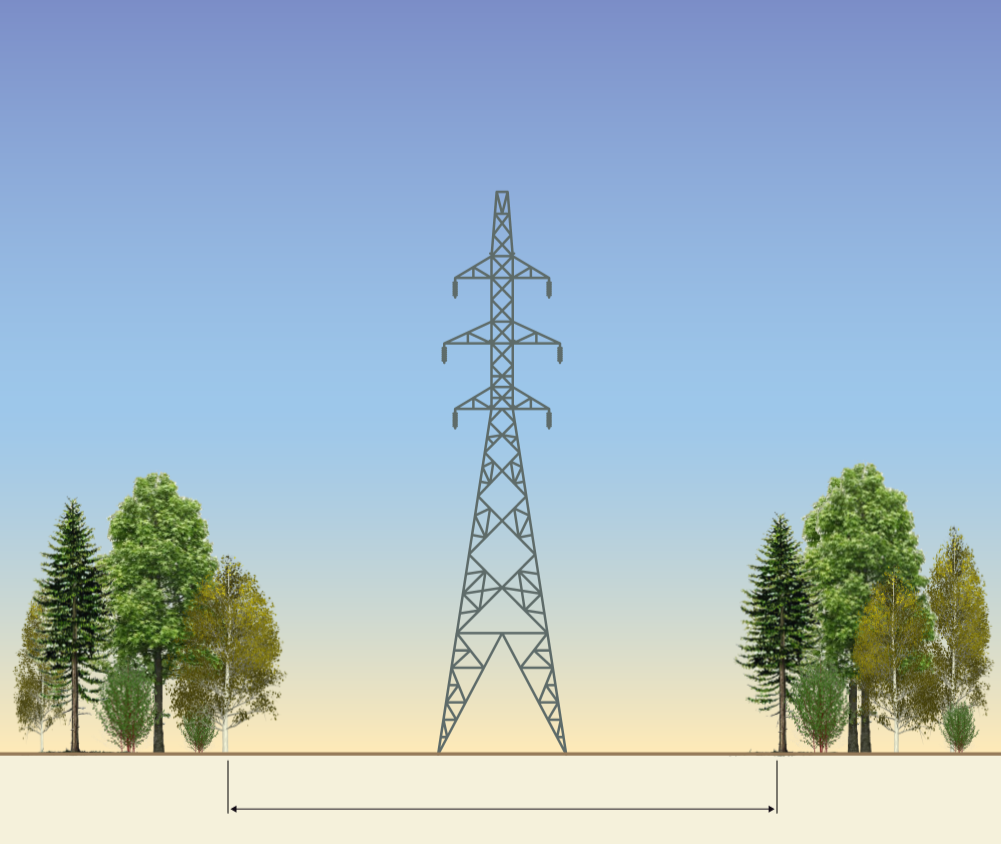

Choosing transmission towers

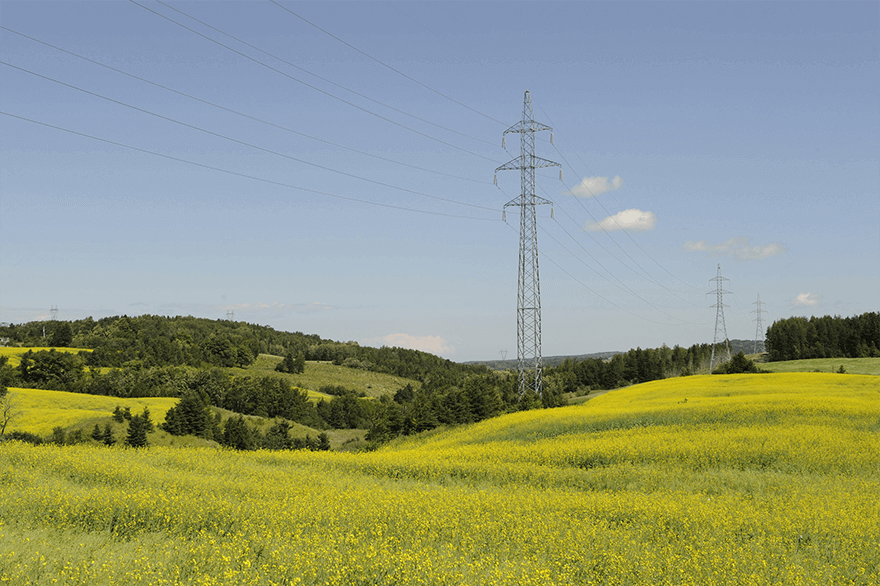

Transmission towers carry power lines and conductors (which are insulated only by the air) at a safe height aboveground.

For technical and safety reasons, line voltage is what determines both tower height and the width of the strip of open land (known as the right-of-way) that’s below and to either side of the line.

The type of tower chosen depends largely on the voltage and number of conductors needed to transmit the electricity. In general, the higher the line voltage, the taller the towers and the wider the right-of-way.

Other technical and environmental considerations play into the choice of towers. Depending on the project and environment, different tower types might be used along a same line route.

After the 1998 ice storm, Hydro-Québec had to rethink the design criteria for a number of tower types. The new towers aren’t necessarily bigger than the old ones, but they’re stronger and more robust, built to withstand higher ice loads and stronger winds.

Presenting the optimized project and mitigation measures

At this stage, the team presents the optimized project, following studies and discussions with the community, complete with the selected line route, the chosen tower type (if the line is overhead) and the final substation location (if applicable). The team also consults with the community to validate the appropriate mitigation measures.

Examples of mitigation measures

- Building in winter to limit soil compaction on farmland from construction machinery

- Landscaping around the substation to mitigate the visual impact

- Addition of/modifications to bike paths, cross-country ski trails, snowmobile trails, etc. near the transmission line

- The final position of the towers is optimized to help integrate them into the landscape.

In some cases, specific measures will be taken to compensate for impacts that cannot be avoided (e.g., land clearing).

Integrated Enhancement Program (IEP)

For almost 35 years now, Hydro-Québec’s Integrated Enhancement Program (IEP) has been working to improve quality of life in the communities that host our new transmission facilities (substations and lines). Under the program, we provide municipalities affected by our projects with funding for community-chosen initiatives.

More information on the Integrated Enhancement Program

Finding the best solution is therefore a collaborative undertaking, involving studies and discussions spread out over several months, and taking into account many different social, environmental, technical and economic concerns.

At the end of the day, it’s an exercise in balance and compromise. Still, we must keep in mind that the infrastructures we build respond to a real need and ensure transmission system reliability.

After the studies and consultations… what happens once the project is optimized?

It generally takes 18 months of technical and environmental studies and public consultations with the host community to develop a power line or transmission substation project.

After this, the authorizations required under applicable laws and regulations are requested from the government authorities

For larger projects, studies are synthesized and submitted to the Ministère de l’Environnement et de la Lutte contre les changements climatiques. Depending on the project in question, up to a dozen government departments might weigh into the analysis to ensure every aspect of the project is reviewed. In these cases, the decrees needed to proceed with construction are ultimately issued by the Conseil des ministres du Québec. Some projects are also submitted to the Commission de protection du territoire agricole (Québec’s farmland protection commission).

Major projects also undergo a detailed review by the Régie de l’énergie to ensure that their technical features constitute justified, fair and informed choices in terms of meeting the needs of Quebecers.

Other authorizations may also be required, depending on the scale of the project or its environment.

Once the project is approved, detailed engineering, procurement and construction begin

Once a project has been approved, the project team performs the detailed engineering and ensures that all required services, equipment and materials are procured. The resources needed for the jobsite are also hired at this time.

For power line projects, each tower on the line is a jobsite in itself. The job involves accessing the site, transporting the materials, building the foundations, assembling the tower on the ground, erecting it, adding the components and unspooling the cables.

To find out more about building a power line

To find out more about building a transmission substation

The many kinds of expertise involved in building a power line or substation

Building a power line or substation is nothing less than a remarkable team effort. Dozens and even hundreds of workers put their skills and know-how toward completing this project that’s destined to enhance the collective well-being for decades. You probably know someone who’s working or has worked on a transmission project in Québec.